I spent lunch time today carrying out a few kayak repairs by welding up a couple of boats. The first was a 6 month old Pyranha Karnali which had been damaged after its pilot left it to run the Morriston River Race by itself. First impressions indicated that the nose of the boat has been turned up, however the hull shows no sign of deformation.

I have therefore concluded that the deck has actually been compressed. The marks to the grab handle support this and the deck isn’t quite level. During that compression the boat has been torn open. This is fairly impressive as the plastic is around 1cm thick in this area. The repair was very easy.

The second boat was a Bliss Stick Huka. The crack in the boat was pretty bad. A superficial repair had been attempted in the past and a great deal of the original plastic had receded, thinned out and deformed. This had resulted in the crack in the hull being too wide for a normal repair. To make matters worse the position of the damage didn’t allow for safe access from the inside.

I therefore decided to build up the repair with some additional material to compensate for the thinning of the old repair. Four or five passes were required before I was happy with the repair. Although this one doesn’t look very pretty it feels and sounds solid.

Liquid Logic Stomper:

Thanks to a rocky ditch in Scotland and a very trusting Nathan Butler I spent a few hours this evening welding a Liquid Logic Stomper back together.

The split in the hull was fairly substantial being around 25cm long and stretched from just in front of and then under the seat. The first job was to remove the seat. This was really easy and took a couple of minutes. The parts were put safely to one side. The repair tape was removed and the split cleaned out and trimmed to expose fresh plastic.

Most people are pretty familiar with the technique of drilling each end of the split and then filling the crack. This simply seals the split and more than likely it will come back. Welding on the other hand joins the two sides of the split with additional material so it essentially becomes one.

I used a variable heat air gun and some 4mm HDPE welding rods. A total of 2 rods were used which represents around 60cm of additional material. The key is judging the level of heat required. Too much and the boat will be wrecked, not enough and the weld will not take.

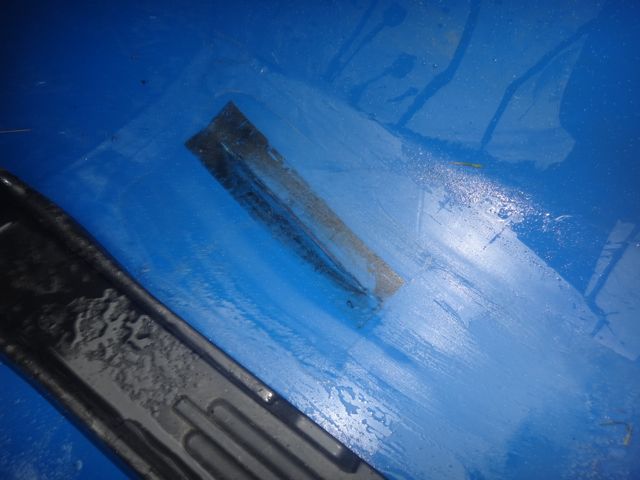

The image above shows the results after the first pass. The marbling effect shows that the plastic is being mixed.

The image above shows the results after the third pass. After the third pass I checked the quality of the repair from the inside and then ran couple passes of welding rod on the inner part of the damage.

The image above shows the first pass on the inside of the Stomper. The excess new plastic was trimmed back and the boat was then put back together. I used a screwdriver to align the seat, seat nut and backrest bracket.

Pyranha Burn:

I spent a couple of hours last night repairing a Pyranha Burn. The boat is around 6 months old and looks it. Very little wear for a creek boat. The split was under the seat and approximately 20cm long.

Before:

After:

The repair feels and sounds solid.

Was the first boat Martyn Butlers karnali if so i think you would be impressed/depressed to see what the boat looks like now after a couple of empty runs in france and a new frankennose cone.

It is Martyn’s Karnali.

you do need to make sure you have the exact same plastic to use as a weld rod though!! I had a crack in My Fluid so I got Fluid to send me some sticks of hull material that were used as welding rods.

Same type yes.

I appreciate you helping me learn more about kayak repairing. I have just seen a kayak twice in my life. The first time? It was sailing in the water while the second one was when my cousin was checking its damages. As far as I remembered, he asked somebody to repair it since he was unable to fix it!